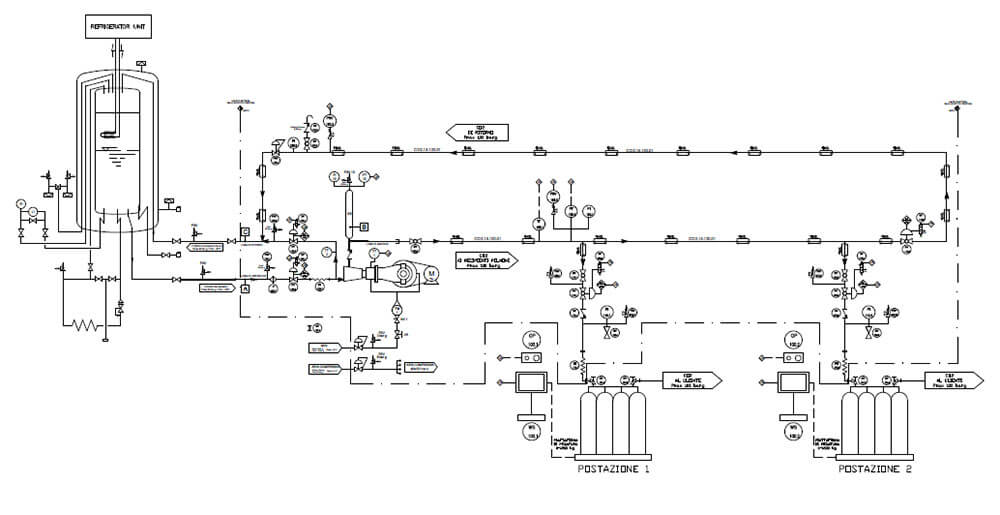

The following is a representative P&I diagram of a plant for packaging CO2 liquid.

Cryogenic fluid storage tank

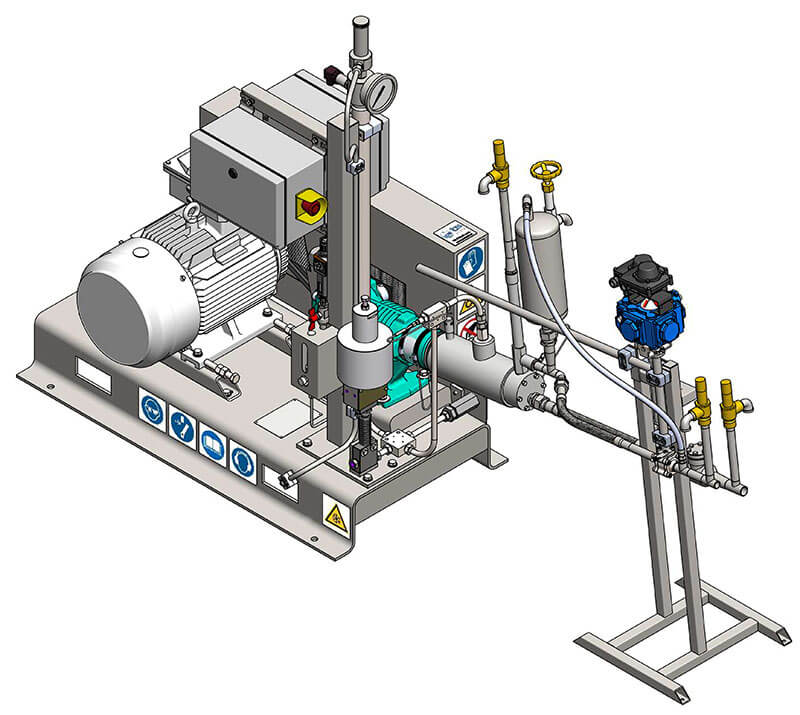

Pumping unit and related electrical control panel

Fluid distribution lines (or plant )

Fluid distribution lines (or plant )

Vessel filling stations, equipped with valves, filling hoses, weighing systems and other accessories

Operator interfaces, with touch screen terminals and confirmation buttons

In-fill receptacles

MAIN FEATURES

- Service pressures: up to 100 bar g

- Service temperature: -40...+80°C

- Valve equipment: multiple versions and configurations available

- Both manual and automatic process management configurations available

- For complete automation configurations, intuitive management software with simple and ergonomic operator interface solutions

- Piping material, stainless steel

- Main materials of structures: painted carbon steel, stainless steel, aluminum

- Variable equipment sizes depending on available space or customer specifications

- Weighing systems with PROFINET protocol

- Availability of configurations, and software versions, for filling medical products

- Availability of SMART INDUSTRY - INDUSTRY 4.0 configurations.

BENEFITS

- More than 30 years of experience in the design and manufacture of high-pressure compressed gas equipment

- Versatility of equipment and valves, marked by modular configurations that can easily compose and adapt to different specific requirements and installation contexts

- Robustness of structures

- Ease of assembly and installation, the equipment and associated assembly manuals are designed to provide the user with appreciable ease of assembly and installation

- Care and attention to detail, from design to packaging

OPTIONS AVAILABLE

- Pumping groups

- Reliable solutions for automatic recirculation of product to the storage tank

- Preliminary engineering services, both of the filling process and automation

- On-site installation service

OPTIONS AVAILABLE

- Filling with liquefied gas, CO2 and N2O

PROCESS FLUIDS

- CO2; N2O

COMPLIANCE

- PED Directive

- EIGA Guidelines