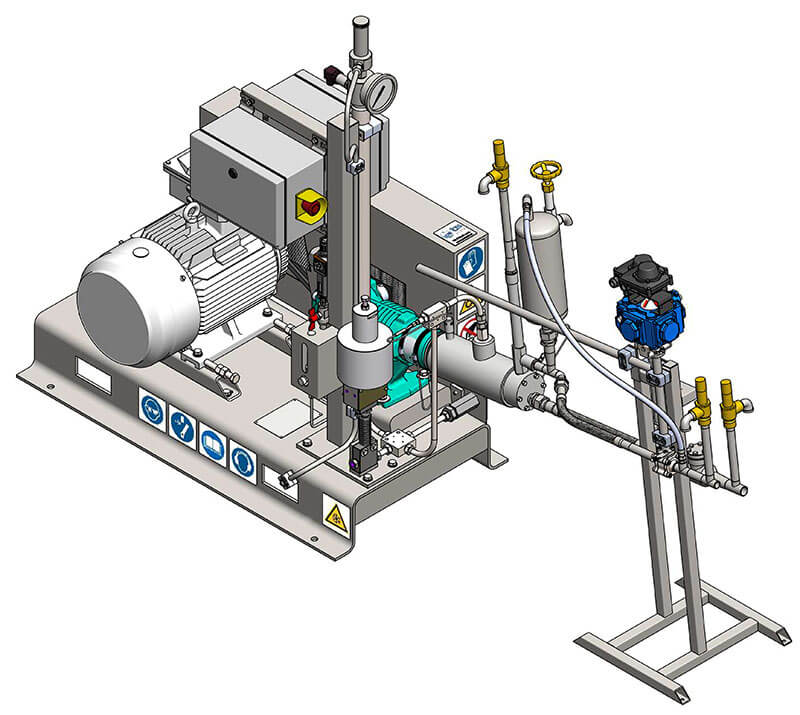

Cryogenic gas vents

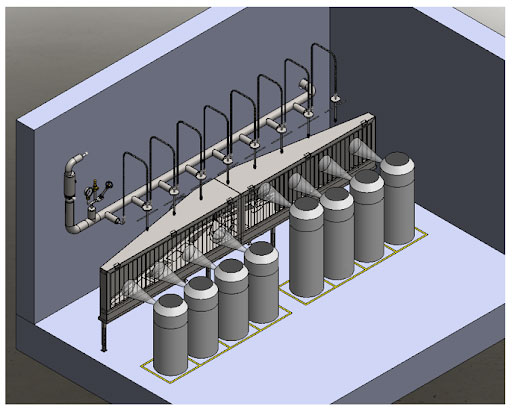

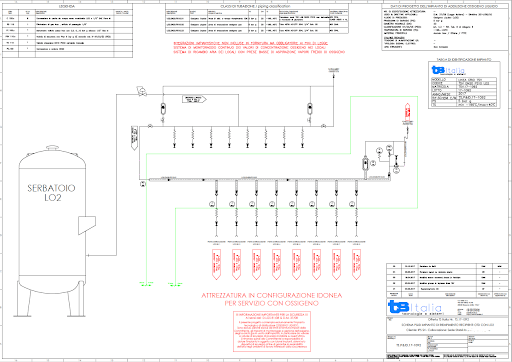

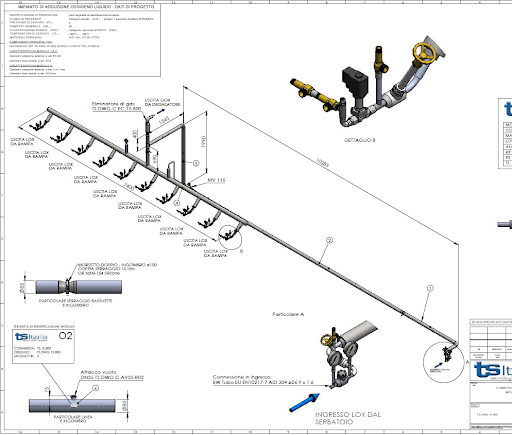

Multi-station filling ramp

Flexible hoses

Flexible hoses

Base unit

Filling stations

Suction system

Items not shown in the figure:

- Liquid medical oxygen storage tank

- Oxygen supply manifold, including pressure regulating valve and other accessories

- Cryogenic O2 transfer line, from tank to filling ramp

Of particular interest: extracting solutions for the removal of exhaust oxygen vapors, which are produced during the filling process and cause poor visibility of filling operations, resulting in risks to operators.*

MAIN FEATURES

- Maximum service pressure (PS or MAWP): 10 bar g

- Service temperature range: -183…50°C

- Main materials: stainless steel, aluminum, brass

- Adduction line and filling ramp thermal insulation solution: TSV (vacuum jacketed insulation)

- Filling hoses equipped with anti-kink springs and UNF end connectors

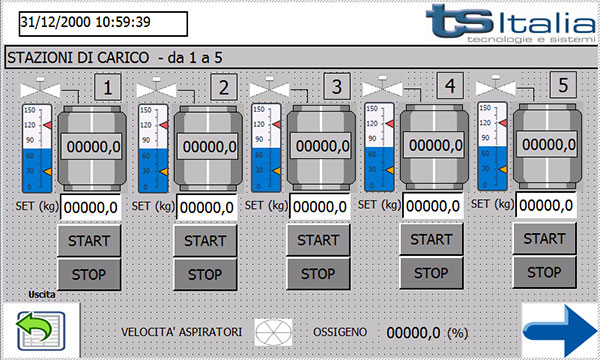

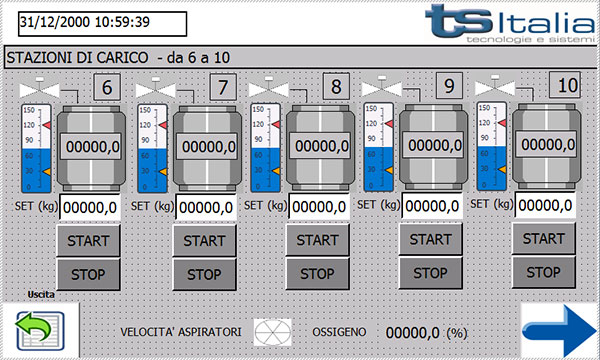

- Configurations available for managing the filling process in both manual and automatic modes

- Intuitive, simple and ergonomic management softwar (only for automated configurations)

- Variable equipment sizes, depending on available footprint or user and context specifications

Sample of TS’s technical dossier:

BENEFITS

- Nearly 20 years of experience in the design and construction of liquid oxygen equipment, with a history of dozens of installations both in Italy and abroad, with thousands of base units filled every day

- Safety, reliability and performance that endure over time

- Homogeneity of liquid oxygen delivery on all filling stations

- Reduced filling times

- For plants equipped with vacuum systems, increased visibility of operations with improved safety for operators

OPTIONS AVAILABLE

- Preliminary engineering services

- Packaging process automation software, based on base unit weighing

- Filling hoses in configuration

superinsulated vacuum jacket - Fill-in connectors (also called fill-heads) for any make or model of base unit

- Adapters for connecting filling hoses to different models of base units available on the market

- Devices for automatic hose retrieval by calibratable mechanism with spring return

- Quick connectors for sampling the purity of oxygen packed in vessels

- Complete systems for sampling the purity of oxygen packed in vessels

- On-site installation service

FIELDS OF APPLICATION

- Filling base units (home oxygen therapy units) with liquid oxygen

PROCESS FLUIDS

- Oxygen

COMPLIANCE

- PED Directive, for cases where classification in one of the Categories is not provided, compliance with the requirements of Art. 4.3 of the Directive itself, with particular reference to the Rule of Art in accordance with specific standards and guidelines

- EIGA Guideline Doc. 33/18 – Cleaning of Equipment for Oxygen Service.

- EIGA Guideline Doc. 217/19 – Vacuum-Jacketed Piping in Liquid Oxygen Service

(*) Under unfavorable climatic conditions, which where present are generally concentrated in a few weeks per year, given by the combination of relative humidity >85% and temperature < 4°C, such suction solutions provide a technological limitation against which the movement of oxygen vapor and air alone cannot provide appreciable improvements in visibility. These circumstances therefore require the integration of additional solutions that must necessarily take into account the installation context and utilities present at the filling center.